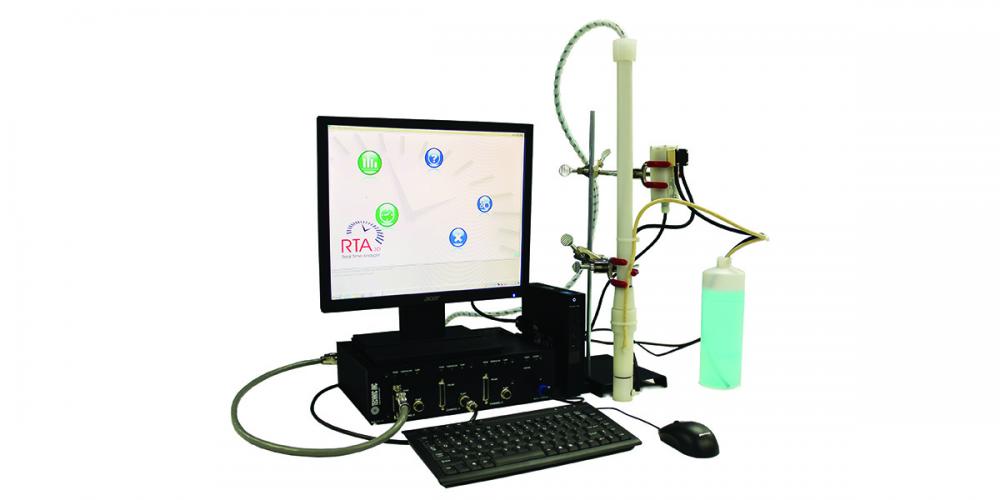

Real Time Analyzer with expanded capabilities and advanced calibration tools

Cranston, RI, USA –Technic’s Analytical Controls group officially announced the introduction of the Real Time Analyzer RTA 3D. The RTA 3D is a much-anticipated upgrade to the RTA, which has set the standard for robust analytical performance in electroplating solutions over the last decade.

Historically, the RTA’s highly reliable design has been consistently responsible for delivering trouble-free and accurate electroplating solution analysis. Now, with the culmination of several years of lab and field experience, the RTA 3D system combines successful technologies utilized by the well-established RTA system with new features that further improve accuracy and reproducibility.

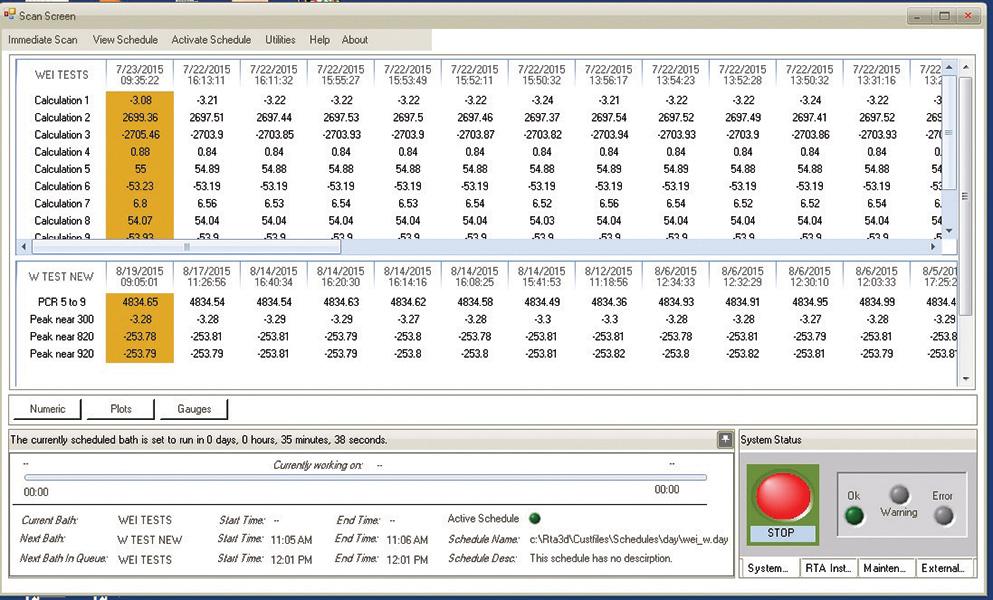

New analytical approaches and innovative electrochemical techniques have made it possible to widen analytical model control ranges and improve accuracy. Updated hardware advancements, including state-of-the-art electronic components, help minimize the impact of external noise while enhancing relevant signals affecting measurement readings. Coupled with intelligent software, the RTA 3D delivers tighter process control and offers users the ability to self-diagnose and even self-correct a variety of hardware issues and miscellaneous disturbances.

Most notably, the RTA 3D integrates a new “logic” feature that automatically makes adjustments based on information obtained from customer data; this allows the unit to self-correct minor issues and create customer-specific parameters. Building on the success of Technic’s original RTA, designed to communicate across many platforms, the open architecture of the RTA 3D makes customization even easier. The system easily integrates into any closed loop/in-line/at-line environment with minimal customization to software. Additional options such as software enhancements, plating health detection, and automatic calibration tools are also available.

Learn more about Technic's full line of Process Control Products