Dual Action Revolution & Rotation Mixers

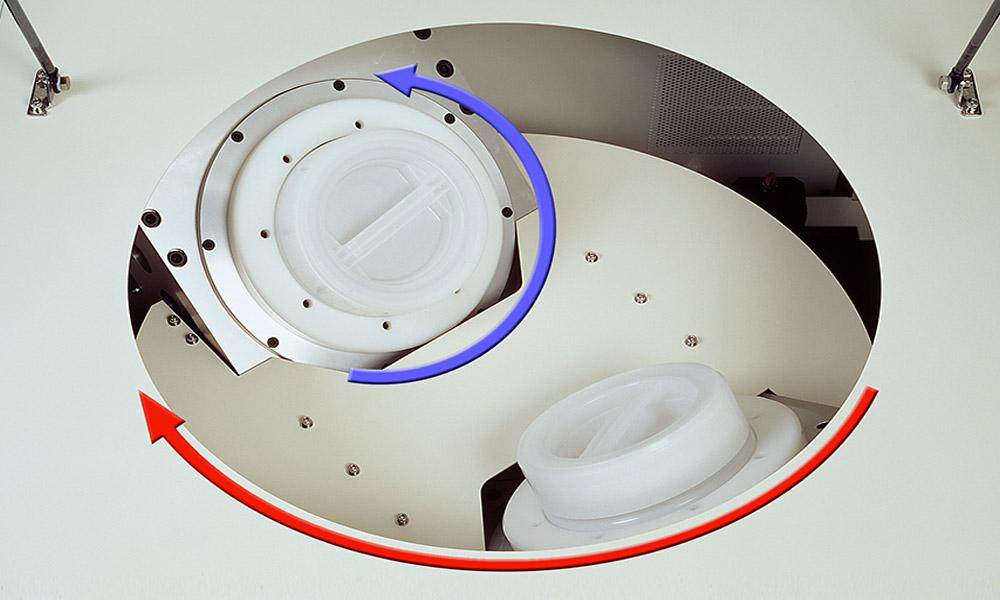

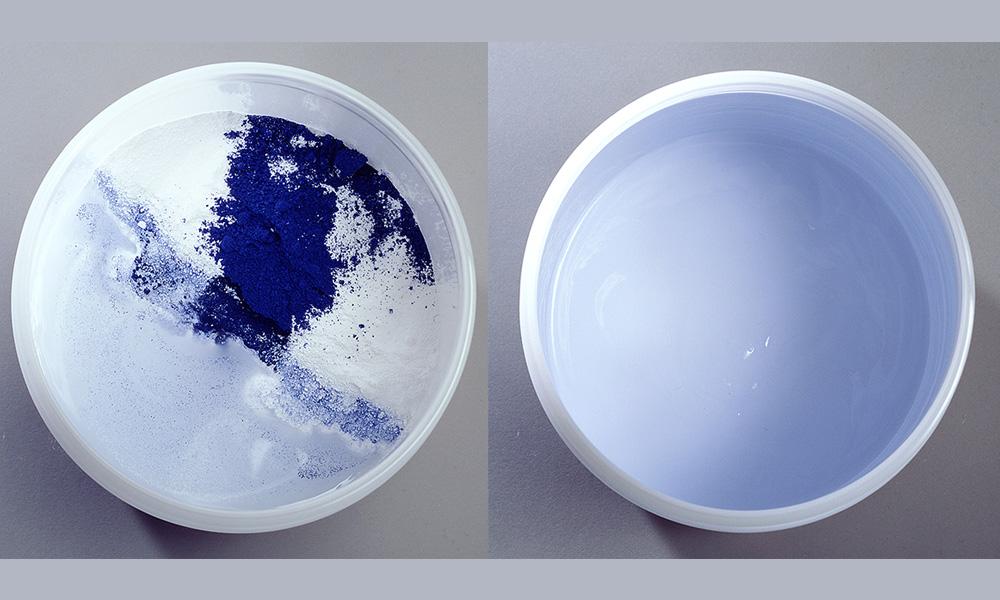

Mazerustar® planetary mixers provide fast and thorough mixing and deaeration simultaneously. Achieved through continually revolving and rotating the container concurrently, the unique dual rotation action eliminates the need for mixing rods, blades, or media, or an evacuation device, and can dramatically reduce processing times.

Applications

- Conductive/resistance materials such as gold, silver, copper, and carbon paste

- Sealing/insulation materials such as glass and ceramic paste

- Seal/glue materials such as epoxy resin

- Molding materials such as silicone resin

- Mixtures of various color materials, such as ink, paint, and pigments

- Production of dentistry, medical/pharmaceutical, or cosmetic base materials

- Abrasion of precision parts

Questions?

Give us a call 401-769-7000

Applications

The Mazerustar® is particularly useful for the following materials and processing purposes:

- High-viscosity liquids, which were impossible to mix or required long processing times by conventional mixing machines or deaeration devices

- Mixing two or more kinds of liquids that are widely different from each other in their characteristics or specific gravities

- Mixing liquids and powders (filler), which need to be evenly mixed, even if the two kinds of materials are widely different from each other in their characteristics or specific gravities

- High-value-added materials that need to be processed without the influence of containment (contaminants) and require processing with minimal waste

- Work processes that may benefit from reduced time and labor by minimizing processing and device or container clean-up

Performance

The Mazerustar® performs mixing and deaeration simultaneously by continually revolving and rotating the container concurrently.

Both revolution (centrifugal) speed and container rotation (planetary) speed are independently variable. This unique mixing capability allows the operator to design precise solutions for mixing various systems.

Revolution speed and rotation speed can be programmed independently in a stepwise fashion (three steps maximum). This stepwise programming ability allows the operator to treat materials in sequence to achieve optimal mixing results for a wide variety of systems and industries.

Container Options

In addition to standard containers, containers such as disposable cups, commercially available containers, syringes, etc., are available for the Mazerustar® mixers by using adapters (optional).

In particular, for syringes, multiple sets of adapters are available in the mixer series, including the KK-2000 model, which are most suitable for deaeration of paste contained in a number of syringes.

Mazerustar® Demonstration Videos

See for yourself how Mazerustar 's power and versatility enable fast and complete processing of a wide variety of compounds.

KK-250S

KK-250S

Standard Containers: HDPE 250mL container

Max. Processing Quantity: 250g x 1 container

Revolution: 10-level variable (1 - 10)

Rotation: 10-level variable (0 - 9) (0.0 - 1.0 times of revolution speed)

Setting Time: 10 - 990 seconds × 3 steps

Channels: 20 (10 fixed channels and 10 user setting channels)

Power Supply: AC100V or AC200-240V

Electricity Consumption: 650W approx.

Outside Dimensions: 350mm(w) × 420mm(d) × 415mm(h)

Weight: 37kg approx.

KK-300SS

KK-300SS

Standard Containers: HDPE 300mL container

Max. Processing Quantity: 310g x 1 container

Revolution: 4 selectable modes (Mixing, Medium, degassing, and wave)

Rotation: 4 selectable modes (0.0 - 0.4 times of revolution speed)

Setting Time: 0 - 30 minutes X 10 steps (every 1 second)

Channels: 0 - 9 CH (10 Channels)

Power Supply: AC100V or AC200 - 240V

Electricity Consumption: 400W approx.

Dimensions: 340mm(w) × 315mm(d) × 370mm(H)

Weight: 24kg approx.

KK-400W

KK-400W

Standard Containers: HDPE 400mL containers

Max. Processing Quantity: 400g x 2 containers

Revolution: 10-level variable (1 - 10)

Rotation: 10-level variable (0 - 9) (0.0 - 1.0 times of revolution speed)

Setting Time: 10-990 seconds × 3 steps

Channels: 20 (10 fixed channels and 10 user setting channels)

Power Supply: AC100V or AC200 - 240V

Electricity Consumption: 750W approx.

Dimensions: 400mm(w) × 513mm(d) × 457mm(h)

Weight: 51kg approx.

KK-1000W

KK-1000W

Standard Containers: HDPE 1.1L containers

Max. Processing Quantity: 1kg x 2 containers

Revolution: 10-level variable (1 - 10)

Rotation: 10-level variable (0 - 9) (0.0 - 1.0 times of revolution speed)

Setting Time: 10 - 300 seconds × 3 steps

Channels: 20 (10 fixed channels and 10 user setting channels)

Power Supply: 200 - 240V (Single Phase)

Electricity Consumption: 2kW approx.

Dimensions: 565mm(w) × 597mm(d) × 700mm(h)

Weight: 140kg approx.

KK-2000

KK-2000

Standard Containers: Specified by user, maximum capacity is 2L approx.

Max. Processing Quantity: 2kg x 2 containers

Revolution: 9-level variable (9 - 1)

Rotation: 10-level variable (0 - 9) (0.0 - 0.94 times of revolution speed)

Setting Time: 10-990 seconds × 3 steps

Channels: 20 (10 fixed channels and 10 user setting channels)

Power Supply: 200 - 240V (Three Phase)

Electricity Consumption: 2.5kW approx.

Outside Dimensions: 646mm(w) × 662mm(d) × 730mm(h)

Weight: 220kg approx.

KK-5000

KK-5000

Standard Containers: HDPE 4L containers

Max. Processing Quantity: 5kg × 2 containers

Revolution: 9-level variable (9-1)

Rotation: 10-level variable (0 - 9) (0.0 - 1.0 times for revolution speed)

Setting Time: 10 - 300 seconds × 3 steps Channels: 20 (10 fixed channels and 10 user setting channels)

Power Supply Voltage: 200 - 240V (three-phase)

Electricity Consumption: 7kW approx.

Dimensions: 790mm(w) × 892mm(d) × 1080mm(h)

Weight: 470kg approx.

Vacuum Models

Protected by Japanese public patents, Technic is the exclusive distributor for Mazerustar® in North America. For questions and/or information regarding Mazerustar® planetary mixers, please contact our Engineered Powders division.