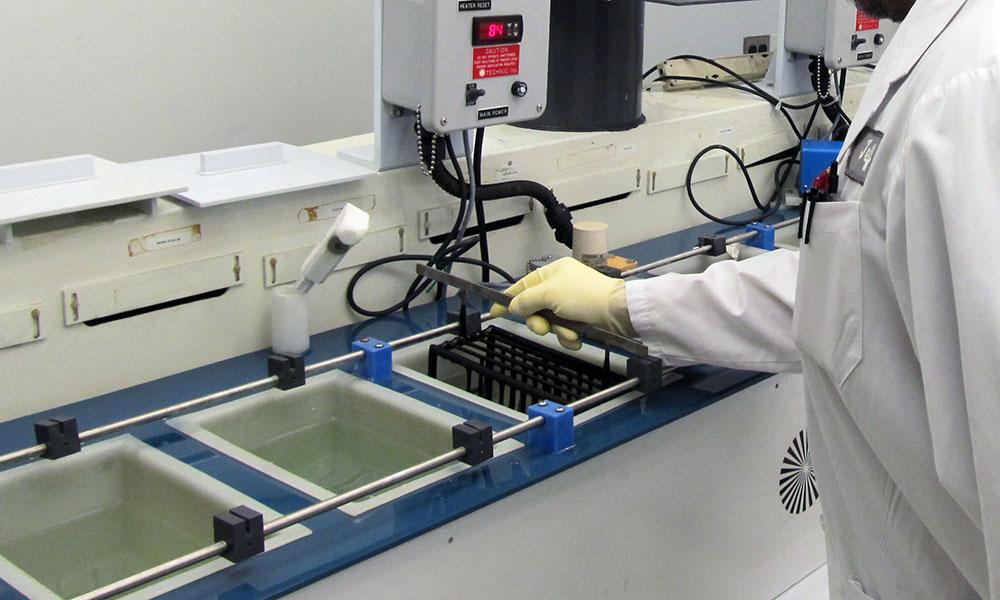

Small Scale Production, Prototype Testing, and R&D

Technic Mini Plating Plants provide countertop small scale production or prototype testing for research and development applications. Mini Labs are available in standard configurations or may be customized to suit your needs. Technic also offer a variety of processing equipment for rack, basket, vibratory and barrel processing.

Mini Plating Plant 5

Standard Features

- Six (6) polypropylene tanks 10 ½” x 6 ½” x 11” deep (3 gallon)

- Two (2) 500 watt Teflon heaters with digital thermostats and low level protection

- Two (2) 10 amp/18 volt DC CC/CV power supplies

- Two (2) 60 minute manual timers

- Polypropylene enclosure 72” x 24” x 25 ¾” high

- 220v/1ph/60hz AC input

Options

- In-tank filter system

- Solid state amp hour/minute meter

- Solid state digital timers

- Air/Solution spargers

- Mechanical agitation system

- Anodes

- Exhaust hood

- Mini Plant Stand

Mini Plating Plant 3

Standard Features

- Four (4) polypropylene tanks 11” x 15” x 11” deep (7 gallon)

- Two (2) 1000 watt Teflon heaters with digital thermostats and low level protection

- Two (2) 10 amp/18 volt DC CC/CV power supplies

- Two (2) 60 minute manual timers

- Polypropylene enclosure 72” x 24” x 25 ¾” high

- 220v/1ph/60hz AC input

Options

- In-tank filter system

- Solid state amp hour/minute meter

- Solid state digital timers

- Air/Solution spargers

- Mechanical agitation system

- Anodes

- Exhaust hood

- Mini Plant Stand

Technic Mini Electroless Copper Line

Designed for small scale testing of copper plating of PCBs plating

Standard Features

- Seven (7) polypropylene tanks 10 ½” x 6 ½” x 11” deep (3 gallon)

- One (1) Stainless steel tank 10 ½” x 6 ½” x 11” deep (3 gallon) with one (1) 500 watt Teflon heater with digital thermostats and low level protection

- Agitation frame with work rods for each tank.

- Overall dimensions are 72” x 15” x 12” deep