Achieve Optimum Side-to-Side and Edge-to-Edge Uniformity

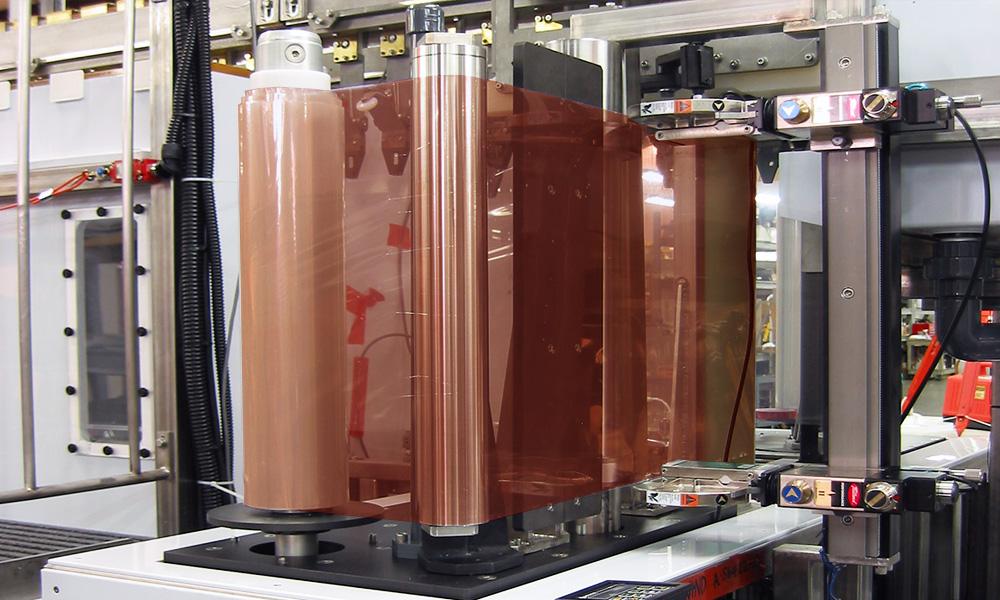

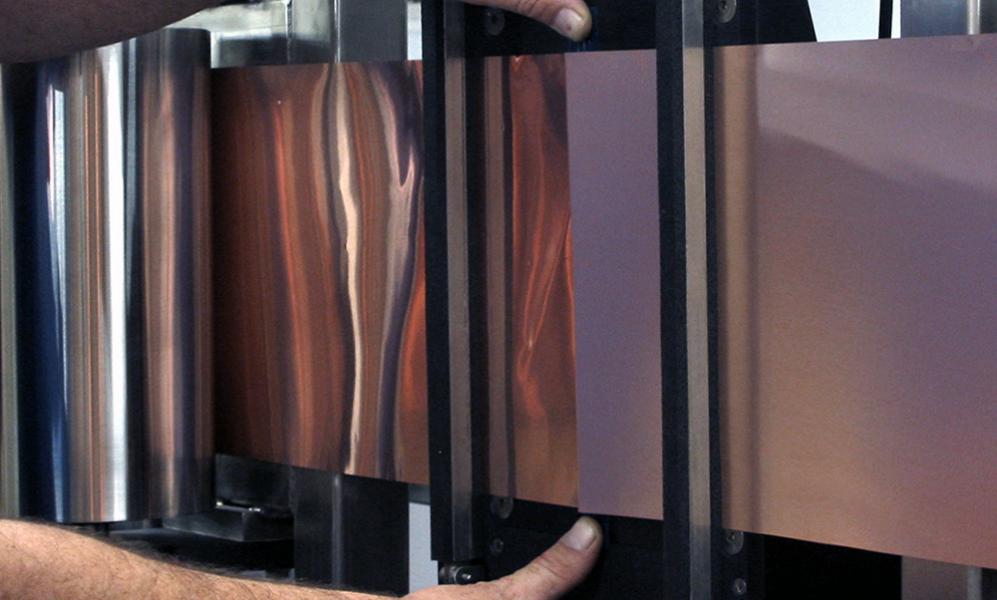

Technic’s MP200CS is an advanced roll-to-roll wet processing system that offers a variety of key benefits for today’s flexible printed circuits, metal foils, and other flexible substrates. Vertical processing is acknowledged as the preferred method for achieving optimum side-to-side and edge-to-edge uniformity.

The MP200CS is the ideal production tool for:

- Base and precious metal plating

- Copper seed, overall panel and pattern plate

- Alloy plating

- Electrocoating

- Electroforming

- Electropolishing

- Chemical etching

- Chemical cleaning

Features and Benefits

- Superior plating with no pits or voids caused by trapped gases

- Flexible platform for roll, panel, or cut sheet formats

- Stable clip mounting platform provides superior dimensional stability

- Single continuous plating cell eliminates step plating

- Repeatable performance with high Cpk

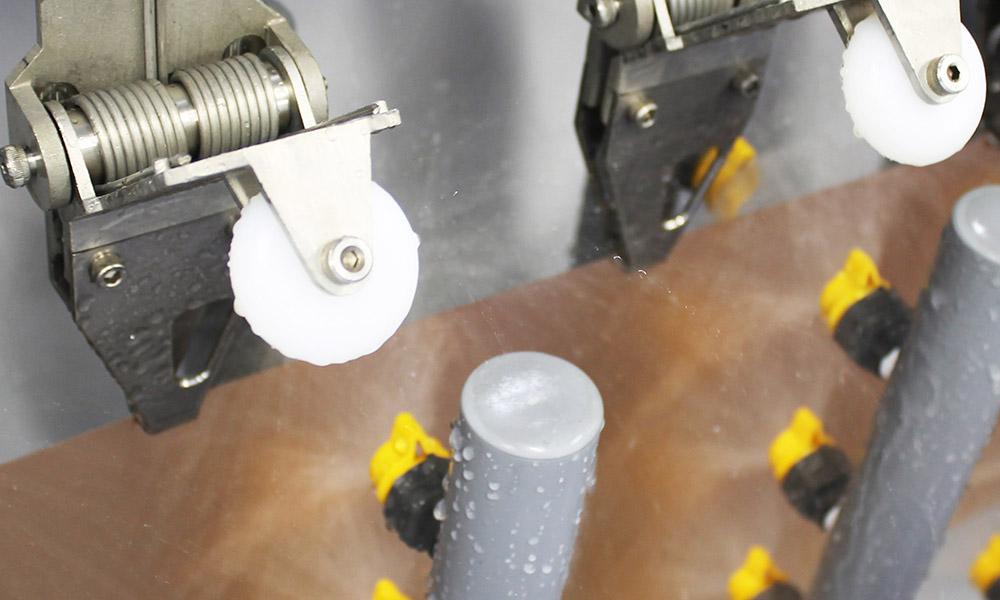

- Bottom transport option with minimal surface contact

- Material handling eliminates scratching, creasing, denting, buckling defects

Advanced Cell Design

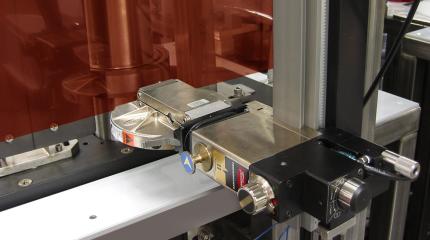

- Isolated cathode compartment, triple filtration, and enclosed tank design provide for cleanest operation

- Anode membrane eliminates oxidation of organic additive

- Adjustable 3-dimensional shield components provide excellent distribution control

- Thickness uniformity to +/-5%

- Current density to 10ASD

- Homogeneous plating with no layer separation

- Choice of titanium basket or IrO insoluble anode

Material Handling

- Total tension from 1kg

- Material width to 600mm

- Film thickness from 12 micron

- Line speed to 40m/min

- Vertical and horizontal spindle orientation

- Edge trimming option

- Auto roll change accumulator

Plating Performance

- Uniform horizontal and vertical distribution

- Plating current flows perpendicular to cathode

- Advanced shielding eliminates edge effects and enables differential plating

- Improved performance with DSA