Metal Etchants for Semiconductor Packaging Applications

Metal etchants are used in semiconductor fabrication and packaging to chemically remove layers from the surface of a wafer during the manufacturing process. This hard mask removal is a critically important step in the process with every wafer undergoing many etching steps before completion.

Technic can provide etchants for most metals used in IC, photoelectronics, MEMS and PV. Technic supplies a range of specialty products for each phase of production and specific application in the etch process. Technic's line of TechniEtch products provide superior results and consistently high performance.

As with all Technic products, we offer our extensive experience and unparalleled customer service that has made Technic a respected resource for quality around the globe.

TechniEtch TBR19

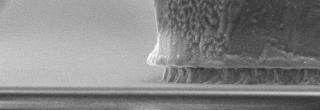

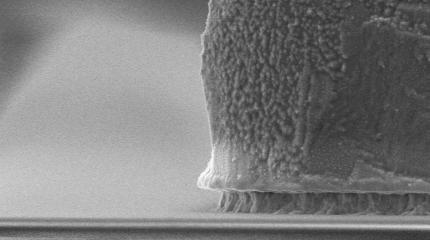

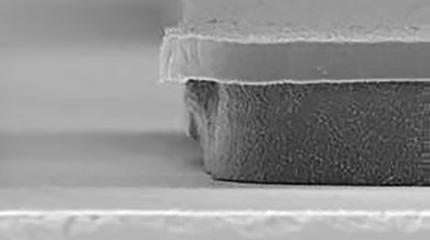

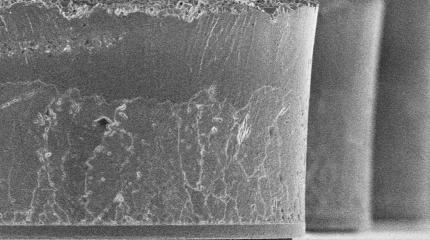

TechniEtch TBR19 is an enabling, fluoride-free aqueous solution, designed to selectively dissolve titanium (Ti) and titanium alloy-based (TiN, TiW) barriers for far back-end of the line (BEOL) interconnect applications. This high-performing metal etchant can significantly reduce undercut. Techni Etch TBR19 is compatible with most UBM and copper pillar integration materials such as Cu, Al, Ni, Sn, and alloys, glass, organic substrate, etc.

TechniEtch CN10

TechniEtch CN10 is an acidic-based copper metal etchant, containing particular additives that greatly enhance stability and metal loading capability in RDL (Redistribution Layer) applications, as compared to conventional oxidative acidic-based solutions. Highly tunable at point of use with great selectivity for UBM Cu and Ni etching.

TechniEtch AC35

Gold (Au) and copper (Cu) etchant offering minimal metal undercutting while performing an effective etching of each or both metals.

TechniEtch ACI2

An iodine-based gold metal etchant that contains highly effective proprietary additives that greatly enhance the stability and metal loading of the solution compared to standard iodine-based etchants. The main attribute of the solution is that the gold etching rate is not impacted by bath loading, aging, and cross-contamination level.

Other TechniEtch Products

TechniEtch SO102 is a "ready to use" fluoride based aqueous solution for TEOS etching, designed to address high resin wetting ability, stable etch rate, and better bath life.

TechniEtch Cr N1 is a standard cerium ammonium nitrate based chemistry formulated to address selective chromium etch.

TechniEtch Al is an acidic buffered solution designed to address aluminum etch.

TechniEtch Mo is a novel blend for optoelectronic and photovoltaic applications, where high selectivity is required between molybdenium and other transparent materials.

TechniEtch CIGS is a novel blend for optoelectronic and photovoltaic applications, where high selectivity is required between CIGS and other materials such as molybdenium.

TechniEtch ZnO is used for transparent electrode, ZnO required designed chemistry to achieve selective etching.