Copper Plating Processes for Decorative Applications

Copper Plating Processes for Decorative Applications

Copper plating processes may vary in composition to satisfy customers’ requirements for specific decorative applications.

Technic offers a variety of copper solutions, such as cyanide, cyanide-free, dye-free, satin, and acid electrolytic copper. Copper’s high throwing power provides excellent adhesion to base metals as well as a flawless, mirror-like deposit.

Thanks to its exceptional corrosion resistance, copper is a popular choice as a functional finish and growing aesthetic in furniture and fashion accessories, such as hand bags and footwear.

Acid copper plating is often utilised as a replacement for nickel-based processes in all decorative applications where nickel-free materials are required. It provides a layer of excellent levelling power underneath the barrier layer (white bronze or palladium plating) and the final layer (gold, silver, rhodium or ruthenium plating).

Glance Cu 160

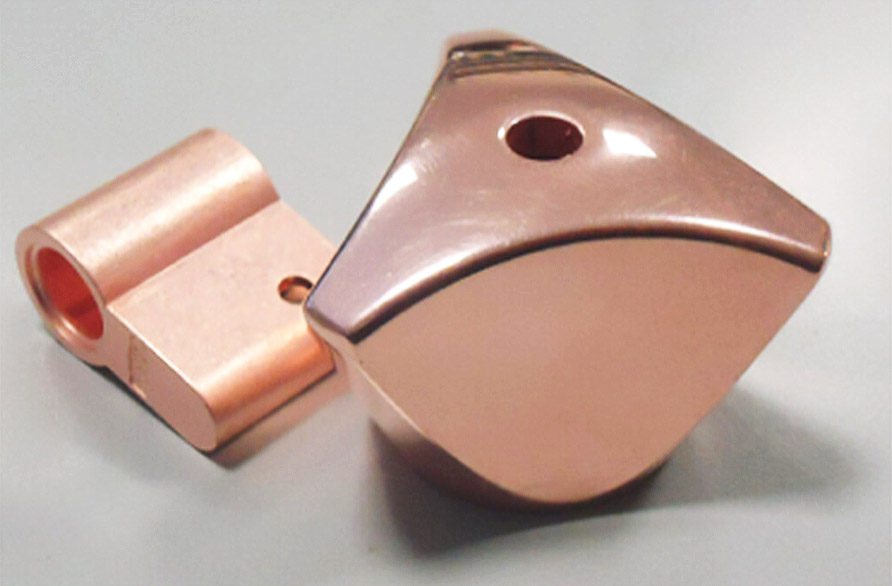

![]() Glance Cu 160 is a cyanide-free alkaline copper plating process, which produces a fine-grained, smooth, dense, and ductile copper deposit, free from porosity and with excellent binding properties.

Glance Cu 160 is a cyanide-free alkaline copper plating process, which produces a fine-grained, smooth, dense, and ductile copper deposit, free from porosity and with excellent binding properties.

The product allows the deposition of copper directly on a wide range of metals such as steel, copper, brass, stainless steel, electroless nickel, and zamak. It is suitable for both rack and barrel applications.

Glance Cu 160 can be used for various types of decorative finishing, e.g. furniture and fashion applications, as well as for industrial applications.

Techni Copper Lux

Mirror bright acid copper plating process for both rack and barrel applications. Capable of high thicknesses with excellent corrosion protection.

Techni Cu No Dyes

Techni Cu No Dyes

Dye-free acid copper plating bath producing bright deposits.

Glance Cu 9002

Glance Cu 9002

Lead-free electrolytic alkaline copper. Suitable for both rack and barrel applications.

Techni ECO Cu 2200

Techni ECO Cu 2200

Cyanide-free alkaline copper. Specifically designed to obtain excellent functionality on zamak.