Bright Tin Acid Process for Rack and Barrel Plating

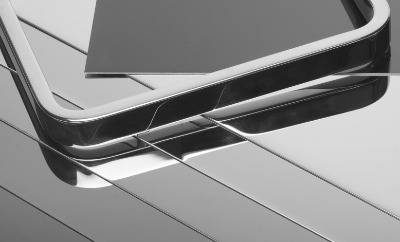

Cranston, RI, USA – Since its much-anticipated launch in 2016, Technibrite HT 1000 has significantly altered the bright acid tin plating industry with over 80,000 liters currently in production globally. With several key advantages in efficacy, cost, quality, and speed of deposit, Technibrite HT 1000 has significantly raised the standard for rack and barrel bright tin plating in both industrial and decorative applications.

Cranston, RI, USA – Since its much-anticipated launch in 2016, Technibrite HT 1000 has significantly altered the bright acid tin plating industry with over 80,000 liters currently in production globally. With several key advantages in efficacy, cost, quality, and speed of deposit, Technibrite HT 1000 has significantly raised the standard for rack and barrel bright tin plating in both industrial and decorative applications.

Based on a cost-effective sulfuric acid electrolyte, the Technibrite HT 1000 process has an exceptional low current density bright range, even when the plating bath temperature and tin concentration parameters are higher than normal. The process can run without a chiller or at temperatures as high as 35˚C, and with tin concentrations as high as 60 g/l. Cathode efficiencies of up to 90% are achievable for Technibrite where the industry standard of leading competitors is only 60—70%. Cycle times can also be significantly reduced thereby increasing the productivity of the plating line by as much as 50%.

Technibrite HT 1000 will improve the appearance and performance of bright acid tin-plated parts, especially parts with complex geometries that often will show dull deposits in low current density areas. The Technibrite HT 1000 process is NPE free and fully RoHS compliant.