MATQu Project Ends After Three Years

After three years, the pan-European MATQu (Material for Quantum Computing) project has come to an end. At the end of May, local partners OrangeQS and Delft Circuits hosted a final review meeting in Delft, Netherlands (fig. 1).

The goal of MATQu was to establish a complete European value chain for building superconducting qubit chips, including critical elements like Josephson junctions and resonators. Key research technology organizations (RTOs) and leading European companies participated in the project.

Technic was particularly involved in the fabrication of new 3D packaging architectures, collaborating closely with RTOs, such as imec and CEA-Leti, as well as BESI, a leading supplier of semiconductor assembly equipment. Technic researchers’ expertise in chemical processes development, including metal plating, selective wet etching, 3D structures cleaning and photoresist stripping greatly added to this project.

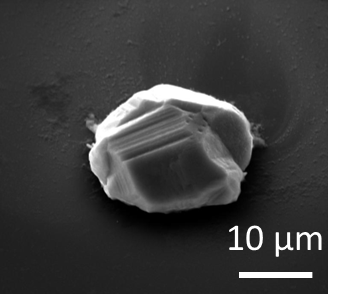

One of Technic's most notable contributions was the development of a new indium plating solution (Elevate Indium D4900) for the growth of indium microbumps (fig. 2). The Technic team also formulated innovative selective wet etchants designed to remove superconducting materials, like ruthenium and niobium, while being compatible with indium.

These novel and rather exotic materials are ideal for assembly, thanks to their superconducting properties at very low temperatures, which is essential for the computing operations of the Josephson junctions in cryogenic conditions (< 1 K).

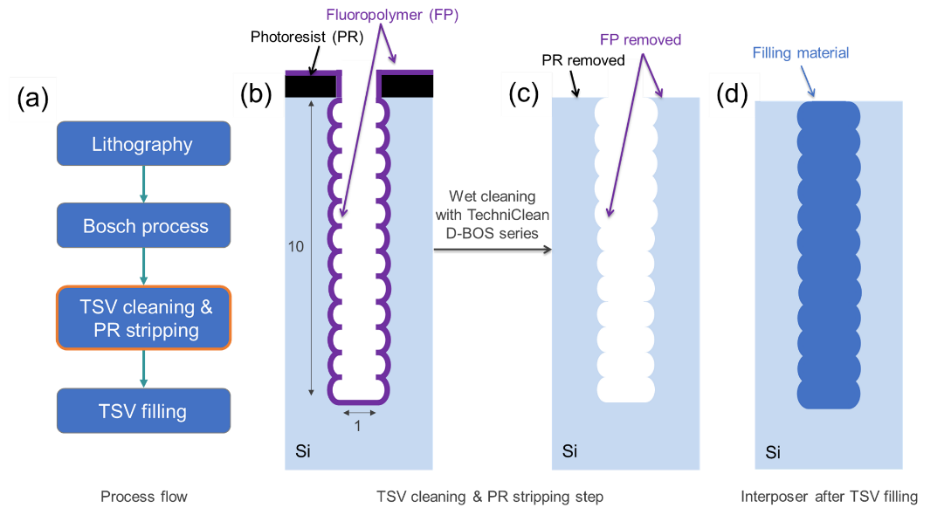

One of the primary challenges in advancing this technology is qubit densification. To solve this problem, researchers devised a 3D design enabling a dense integration of superconducting qubits. This design replaces traditional bonding wires with vertical interconnects, known as Through Silicon Vias (TSVs), which minimize internal signal connection lengths in silicon.

This innovative solution provides several advantages, such as faster operation, reduced heat production, and lower power consumption. Cleaning the TSVs is critical to avoid issues during subsequent processes (fig. 3).

The Technic team was able to develop a cleaning solution to remove the fluoropolymer deposited during TSV fabrication (Bosch process). This cleaning formulation, known as TechniClean BOS 390, was assessed and validated along with MATQu partners.

These collaborative works were also shared during the SPCC 2022 and ECTC 2024 conferences and on scientific journals (MicroElectronic Engineering and IEEE).

Over its three-year duration, the MATQu project demonstrated the capabilities of the European ecosystem to innovate in the fields of quantum elements, assemblies, connectors, and software development, paving the way for the future of quantum computing.

References

https://orangeqs.com/news/matqu_close-out/

SPCC 2022, “Through Silicon Vias Cleaning for Quantum Computer Interconnects Integration”

MicroElectronic Engineering: “Developing TSV wet cleaning chemistry for quantum computing application” (https://www.sciencedirect.com/science/article/abs/pii/S0167931723000758)

ECTC 2024 and IEEE journal, “Process Development and Characterization of Ru-based UBM for In Bumps Integration for Quantum Computing Applications”