Copper Plating

Wide-ranging, low current density processes with high-throwing power with excellent leveling qualities..

Low Current Density Copper

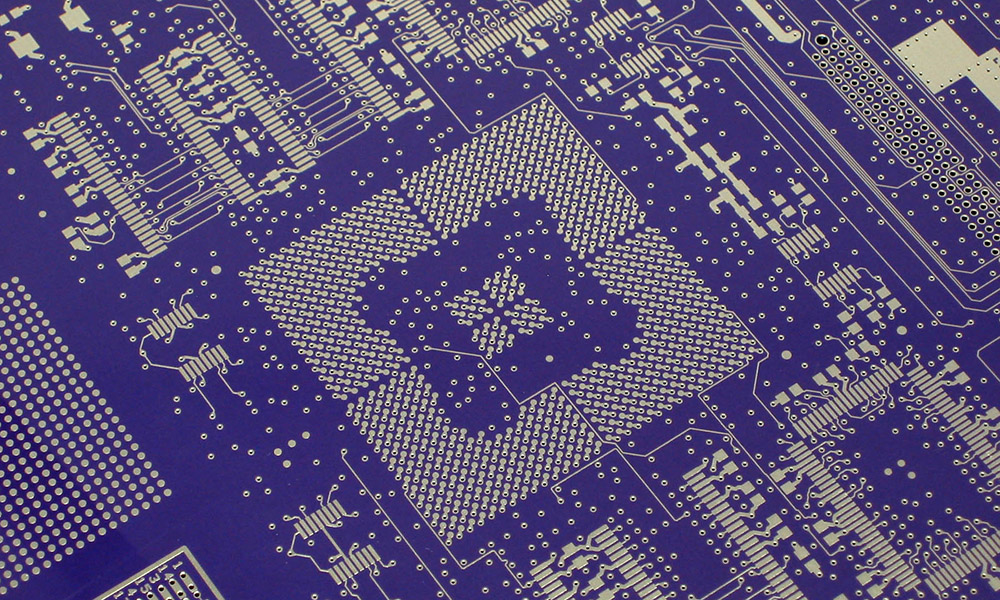

Technic CU 2800 is an electrolytic acid copper process specially designed to provide excellent distribution when plating through-hole printed circuit boards over a wide range of Low current densities. The electro-deposit produced by the Technic CU 2800 process are fine-grained equiaxed, high purity, ductile copper deposits that will meet or exceed all the requirements of MIL-P-55110-F and BS9760. The process utilizes a single component for cost-effective replenishment. All the components in the process are fully analyzable and the Technic CU 2800 process is specifically optimized for control by the Technic EBA (Electroplating Bath Analyzer) or other approved electrochemical analysis methods.

Technic CU 135 is an electrolytic acid copper process for use with insoluble anode systems like Technic ISA. It is designed to provide excellent distribution when plating through-hole printed circuit boards over a wide range of Low current densities. The electro-deposit produced by the Technic CU 135 process are fine-grained equiaxed, high purity, ductile copper deposits from an economical, two-additive system that will meet or exceed all the requirements of MIL-P- 55110-F and BS9760. All the components in the process are fully analyzable and the Technic CU 135 process is specifically optimized for control by the Technic EBA or other approved electrochemical analysis methods.

Download the Electrolytic Copper Fact Sheet

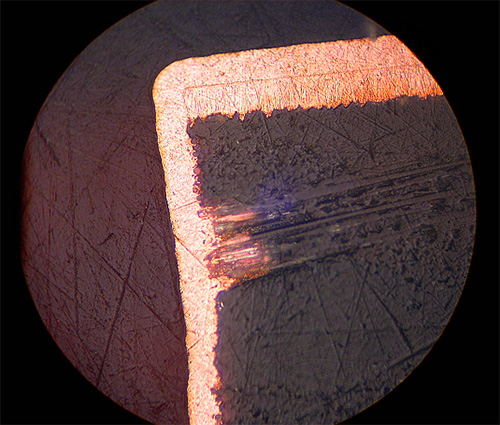

High Current Density Copper

.jpg)

Technic CU 128 is an electrolytic acid copper process specially designed for plating flexible and thin rigid printed circuit boards. It is designed to work in high impingement, high speed, very high current density plating equipment, like Technic’s MP200 & MP100. Can be used with insoluble anode systems like Technic ISA. The electro-deposit produced by the Technic CU 128 process are fine-grained equiaxed, high purity, ductile copper deposits from an economical, two-additive system that will meet or exceed all the requirements of MIL-P-55110-F and BS9760. Technic CU 128 is specifically designed for improved lateral growth on weakly activated surfaces like carbon or graphite-based direct metallization systems. Technic CU 128 provides a wide window to maintain excellent ductility while overcoming imperfections in the substrate and initial metallization. All the components in the process are fully analyzable and the Technic CU 128 process is specifically optimized for control by the Technic EBA (Electroplating Bath Analyzer) or other approved electrochemical analysis methods.

.jpg)

Request more information on our copper plating products for PCB

Download Electrolytic Copper Fact Sheet

Tin Plating

Highly effective Tin plating for PCB fabrication

Techni Solder Matte NF 820 HS is an electroplating process for the deposition of 63/37 tin/lead alloy or 100% pure Tin in rack plating applications. Techni Solder Matte NF 820 HS provides a white-grey matte deposit from a methane sulfonic acid-based system. The Process parameters are extremely flexible and are ideal for high throwing power.

Techni Solder Matte NF 820 HS is an electroplating process for the deposition of 63/37 tin/lead alloy or 100% pure Tin in rack plating applications. Techni Solder Matte NF 820 HS provides a white-grey matte deposit from a methane sulfonic acid-based system. The Process parameters are extremely flexible and are ideal for high throwing power.

Request more information on our tin plating products for PCB