Semiconductor Electroless Tool for Mid to High Volume Applications

With the growth of ENIG and ENEPIG for wire bonding or soldering of semiconductor dies, the need for production-proven plating equipment has become critically important. While there are many good options on the market for purchasing semiconductor ECD tools for high-volume manufacturing, electroless and immersion plating require a much different type of tool. The unique and specialized aspects of designing a plating cell for successful and consistent electroless and immersion plating are well known by the engineering staff at Technic’s Surface Finishing Technologies Group. The Semcon 2500 plating tool is the culmination of years of experience designing such tools and is fully compatible with any commercially available electroless, immersion, and ancillary chemistries as well as Technic’s exclusive line of Elevate brand chemistry for ENIG and ENEPIG.

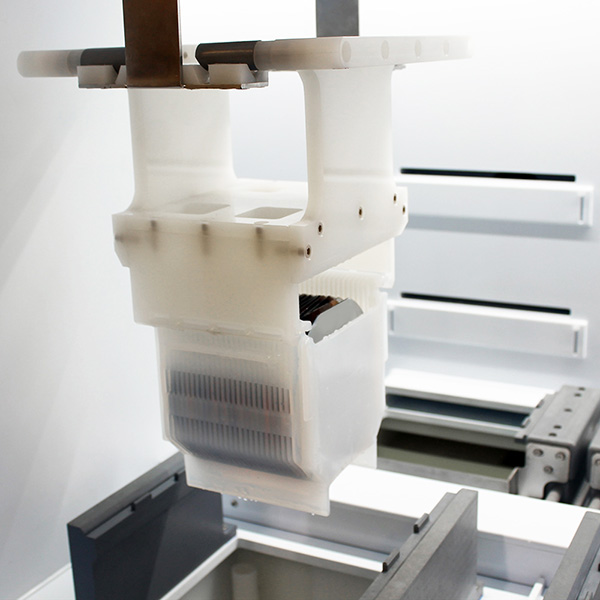

The Semcon 2500 is a tri-axis, fully automatic, cleanroom-rated plating tool for deposition of electroless nickel, electroless palladium, immersion gold, immersion palladium, and immersion silver chemistries. The system processes wafers from 50 – 200 mm using custom or commercially available wafer cassettes. The Semcon® 2500 offers ease of operation with multiple programming options, easy changeovers, with convenient maintenance access all in a space-saving and highly reliable tool.

The Semcon 2500 is a tri-axis, fully automatic, cleanroom-rated plating tool for deposition of electroless nickel, electroless palladium, immersion gold, immersion palladium, and immersion silver chemistries. The system processes wafers from 50 – 200 mm using custom or commercially available wafer cassettes. The Semcon® 2500 offers ease of operation with multiple programming options, easy changeovers, with convenient maintenance access all in a space-saving and highly reliable tool.

Automation for Electroless Plating

Features

- Tri-axis cleanroom grade automatic hoist with dynamic scheduling software

- Rotomolded tanks designed with rounded corners for reduced plateup

- Independently adjustable flow controls in processing cells and reservoirs

- Multi-recipe management system with data logging for traceability

- Chemical dosing and filling system with programmable mixing sequences

- Choice of custom or industry-standard wafer cassettes

Benefits

- Turnkey process available including analytical controllers, chemical dosing, and Technic Elevate electroless and immersion chemistries.

- Fully compatible with all Technic Elevate chemistries which reduce time and costs by being able to quickly establish optimum process parameters and efficient control systems.

- Space-saving configurations – process cells configured in two rows vs. single row which results in a slightly deeper but much shorter tool. Fully maximizing valuable cleanroom floor space.

- Extended bath life – rotomolded rounded corner tank design extends bath life by preventing excess plate-out on sharp corners and irregular surfaces.

- Wafer size processing flexibility (50 – 200 mm).

- Reliability and value – designed, fabricated, and installed by an experienced industry leader in electroless and immersion production plating.