Conventional Barrel Processing and Specialized Alternatives

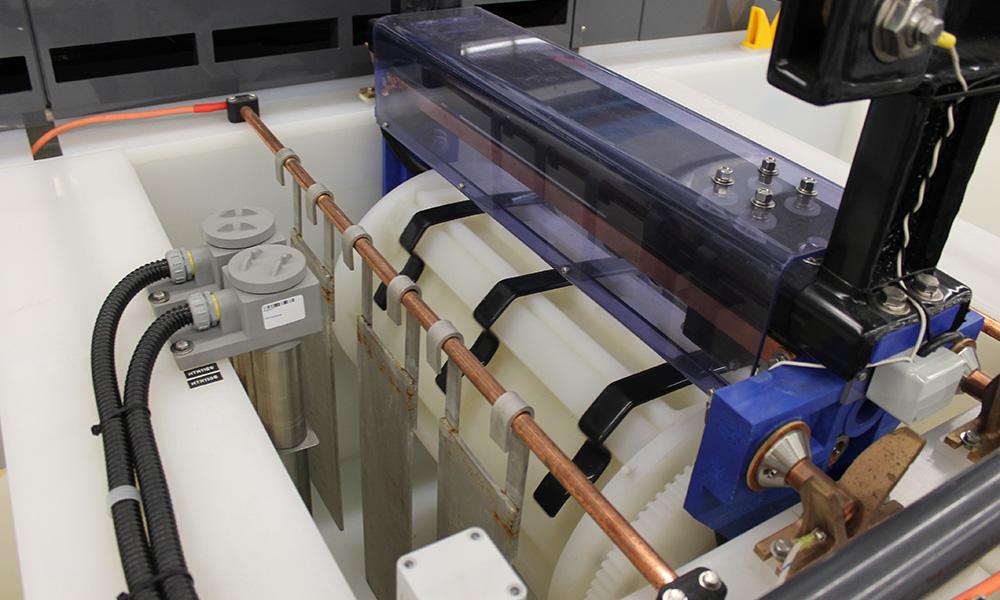

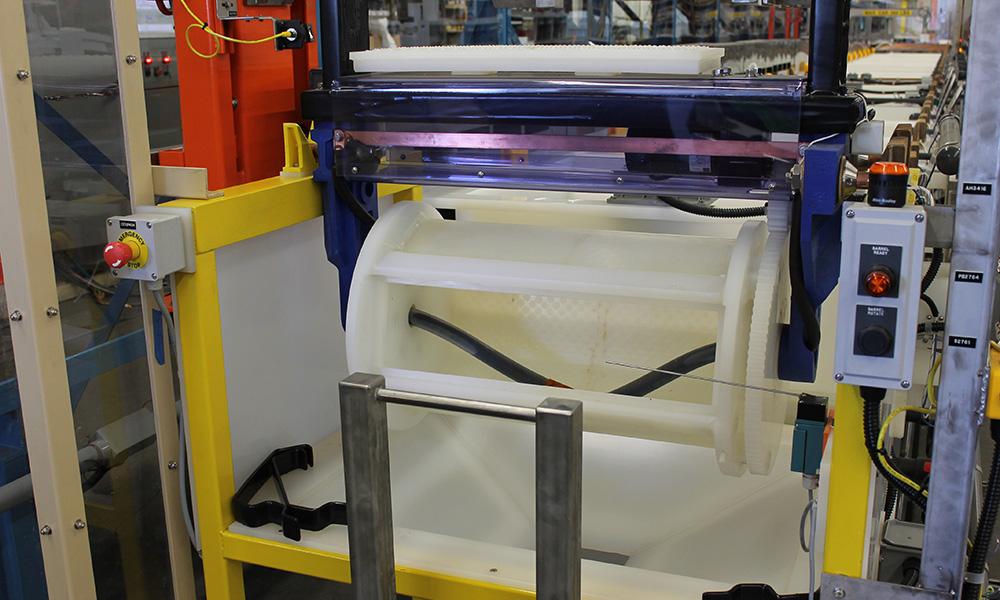

Barrel lines are typically considered for batch finishing of many parts that may be difficult or too costly (labor intensive) to rack plate. Conventional barrel processing consists of a horizontal barrel (varying length and diameter) rotating on a horizontal axis. A DC cathode contact is made either through side mounted danglers or various contacts within the cylinder. Barrel technology is commonly used in conjunction with manual and automatic hoist systems.

Large barrels (e.g., 18” x 36”, 24” x 60”) are used for general metal finishing and industrial applications, while smaller barrels (e.g., 3” x 5”, 4” x 6”, 6” x 12”) are used for more precision parts, such electronic component plating. Technic also provides specialized alternatives (listed below), in addition to conventional barrel technology, with some significant advantages.