Full range of finishing equipment for uniform plating of electronic components, lead frames and connectors.

Technic’s equipment offerings for electronic parts include the revolutionary Spouted Bed® Electroplater (SBE®), automated cut strip plating lines, reel-to-reel plating lines as well as traditional rack & barrel and vibratory finishing technologies.

Technic SBE® - Spouted Bed Electroplater (Rack and barrel plating alternative)

Ideal for small components .005”-.5”, such as electronic connectors, medical devices, discs, pins, socket and passive electronic devices, including those with blind holes. The SBE® packaging chamber will accommodate loads ranging from 50-500 ML. SBE® technology lends itself to manual as well as automatic hoist systems. Known for exceptional uniformity and the reduction of coupling, twinning and clumping.

Controlled Depth Pin Plater - CDP2000

Technic's CDP2000 is a precision electroplating machine designed for high accuracy controlled depth precious metal plating onto loose parts, typically for pins and sockets for the electronic connector industry.

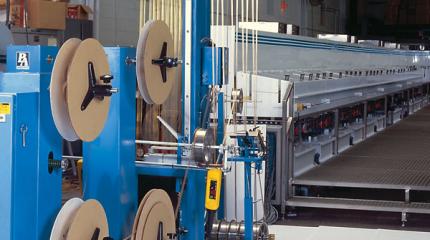

Reel to reel systems

Technic’s Reel-to-Reel Plating Systems offer precise engineering, quality construction and some of the most advanced cell designs and configurations available. Available for a wide range of continuous processing applications, Technic equipment and chemistry is widely used throughout the connector industry.

Barrel Plating Equipment

Technic offers a variety of barrel plating options for the connector industry. Barrel plating is a relatively low cost, high volume solution for a variety of electroplating applications.

Vibratory Barrels

Vibratory barrels combining rack plating quality with barrel plating production at significant savings. Vibratory plating reduces metal consumption by improving end-to-end and part-to-part uniformity. Intricate parts can be uniformly plated in the "blind" areas.