Anodizing equipment knowledge, experience, quality construction, and lasting partnerships with our customers

Why choose Technic for your anodizing equipment?

We know the anodizing process and we build equipment that will empower you to excel in today’s competitive markets. Technic-built systems have set the bar for design, quality, and efficiency to meet almost any budget. Whether your anodizing application is for aerospace, automotive, sporting goods, medical, military and defense, or consumer and recreation goods, we can optimize the system to meet your specific application needs and process requirements.

We know the anodizing process and we build equipment that will empower you to excel in today’s competitive markets. Technic-built systems have set the bar for design, quality, and efficiency to meet almost any budget. Whether your anodizing application is for aerospace, automotive, sporting goods, medical, military and defense, or consumer and recreation goods, we can optimize the system to meet your specific application needs and process requirements.

The anodic coating process you require will define our quotation and build specification. This may be a custom-designed line unique to your application or one of our APEX modular systems that meet your timeframe and budget. Whether your specification requirements are Mil 8625, AMS Aerospace, Alcoa, AAMA, Automotive, Medical, or Titanium 2471, we have you covered.

Our extensive design capabilities, engineering, and construction.

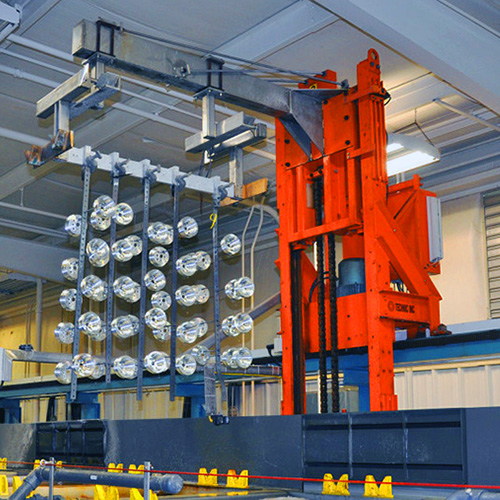

Technic Equipment is the superior choice for automated and manual finishing systems for aluminum surface finishing, aluminum anodizing, and titanium anodizing. The Technic process begins with a thorough information inquiry to understanding your technical and financial requirements. Technic Equipment guides the process from design, to fabrication, with support thru start-up to provide a full turn-key project. We have a full in-house engineering staff to design, build, and manufacture equipment systems all under one roof at our North American facility located in Pawtucket, Rhode Island. Technic’s fully integrated design and construction techniques utilize proven manufacturing standards that provide years of trouble-free operation for our customers. Technic Finishing Systems perform reliably and consistently, day after day. Should you need to refurbish, upgrade, or retrofit your system at any point, Technic has the tools and knowledge to provide a clear path forward to achieve your goals.

Technic Equipment is the superior choice for automated and manual finishing systems for aluminum surface finishing, aluminum anodizing, and titanium anodizing. The Technic process begins with a thorough information inquiry to understanding your technical and financial requirements. Technic Equipment guides the process from design, to fabrication, with support thru start-up to provide a full turn-key project. We have a full in-house engineering staff to design, build, and manufacture equipment systems all under one roof at our North American facility located in Pawtucket, Rhode Island. Technic’s fully integrated design and construction techniques utilize proven manufacturing standards that provide years of trouble-free operation for our customers. Technic Finishing Systems perform reliably and consistently, day after day. Should you need to refurbish, upgrade, or retrofit your system at any point, Technic has the tools and knowledge to provide a clear path forward to achieve your goals.

We provide the best customer service in the industry.

Technic maintains key industry relationships to build and support Technic process lines with full component support now and for the future. Technic assists with the coordination of support systems such as filtration, waste treatment, and ongoing system service and supplies. Technic’s customer-focused support starts with the design and build process, and continues after startup to ensure your ongoing success. Our relationships with our customers have made us one of the most successful and longest operating equipment suppliers in the world. Technic maintains key industry relationships to build and support Technic process lines with full component support now and for the future. Technic assists with the coordination of support systems such as filtration, waste treatment, and ongoing system services and supplies. We have over 35 years of experience building and supplying world-class finishing equipment and over 75 years of chemical process development with hundreds of systems installed and maintained around the globe.

Technic maintains key industry relationships to build and support Technic process lines with full component support now and for the future. Technic assists with the coordination of support systems such as filtration, waste treatment, and ongoing system service and supplies. Technic’s customer-focused support starts with the design and build process, and continues after startup to ensure your ongoing success. Our relationships with our customers have made us one of the most successful and longest operating equipment suppliers in the world. Technic maintains key industry relationships to build and support Technic process lines with full component support now and for the future. Technic assists with the coordination of support systems such as filtration, waste treatment, and ongoing system services and supplies. We have over 35 years of experience building and supplying world-class finishing equipment and over 75 years of chemical process development with hundreds of systems installed and maintained around the globe.

We've compiled an easy view chart to help you determine the features you will want to consider in your anodizing line.

What Technic Anodizing System is right for me?

Laboratory Anodizing Mini-Plant

Our Laboratory Anodizing Mini-Plant (LAMP) is a compact and complete manual anodizing line with a small footprint. It has two compartmentalized stations to provide a full anodizing process.

Apex Series Modular Anodizing Systems

Technic’s Apex anodizing platform offers a modular, system designed for manufacturing companies looking to bringing surface finishing in-house or find the perfect upgrade for outdated hand operating lines.

Custom Turnkey Anodizing Lines

Technic anodizing systems offer the most advanced technology and dependable engineering, as well as quality fabrication for meeting the high demands of today's manufacturing.