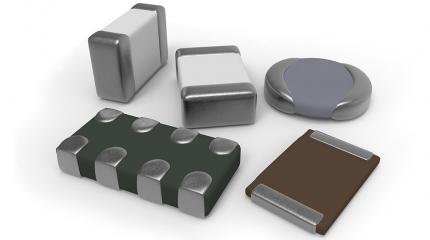

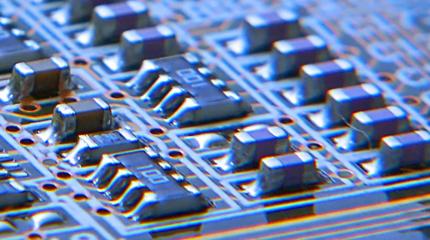

Plating Chemistry for Passive Electronic Components

Resistors, capacitors, inductors, and varistors are all considered passive devices. Technic supplies a selection of Gold, Nickel and Tin plating chemistries as well as Post Treatment Processes and exclusive equipment for a wide variety of Passive Component applications.

Nickel Electroplating

Techni Nickel S

Techni Nickel S is a versatile semi bright nickel process that can be formulated either as a sulfate or sulfamate process. The deposit is virtually stress free and highly ductile. The process can be run at pH 4 to minimize attack on ceramic substrates.

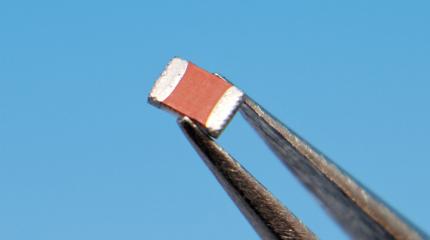

Pure Tin Electroplating

Ceramistan 1031

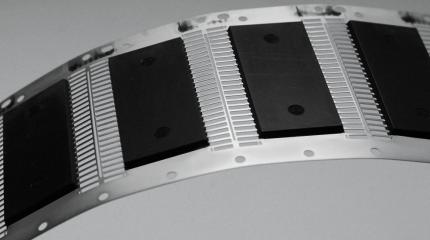

Ceramistan 1031 is a relatively high pH (3.2 – 4.5 pH) pure tin electroplating process specifically designed for electroplating passive electronic components (capacitors, resistors, varistors, etc.). The fine grained deposits exhibit excellent solderability and meet JEDEC whisker resistance requirements. The unique formulation of the 1031 process minimizes coupling/twinning of the parts during plating. Ceramistan 1031 can be used in either the SBE® or traditional barrel plating equipment.

Tin/Lead Electroplating

Ceramistan DM

Ceramistan DM operates at a pH range of 3.0 – 4.0, and can produce deposits with an alloy range of 100% tin to 60% tin, balance lead. The deposits from the Ceramistan DM process exhibit excellent solderability. The coupling/twinning of parts is significantly reduced because of the unique formulation of the Ceramistan DM process. Ceramistan DM can be used in both traditional barrel or SBE® equipment.

Tin Electroplating

Technistan EP

![]()

Technistan EP is a lead-free, high speed pure tin process. This whisker-resistant product is based on Technic’s proprietary and patented mixed acid technology. Technistan EP has been the industry standard in Pb-free plating for more than 10 years.

Techni NF JM8000

Techni NF JM8000 is specifically designed for the ultra high, high, and medium speed deposition of matte tin with minimal tin whisker growth properties. This process provides a lead-free deposit from a methane sulfonic acid electrolyte. The process can be also used for on-line reflow applications.

Post-Treatment

Tarniban® C48/C50

Tarniban® C48/C50 minimizes deposit discoloration during storage and provides improvements in solderability performance after steam age pre-conditioning. Tarniban® C48/C50 also minimizes corrosion-induced tin whisker growth caused by high temperature/humidity exposure.