Sealed Wafer Processing Racks

Designed for use with Technic’s Semcon 1000, 2000, and 2500 manual and automatic wafer/panel plating tools. These racks are currently utilized across various applications, including Copper, Nickel, Gold, Tin, and Tin/Lead plating on both single and double-sided substrates.

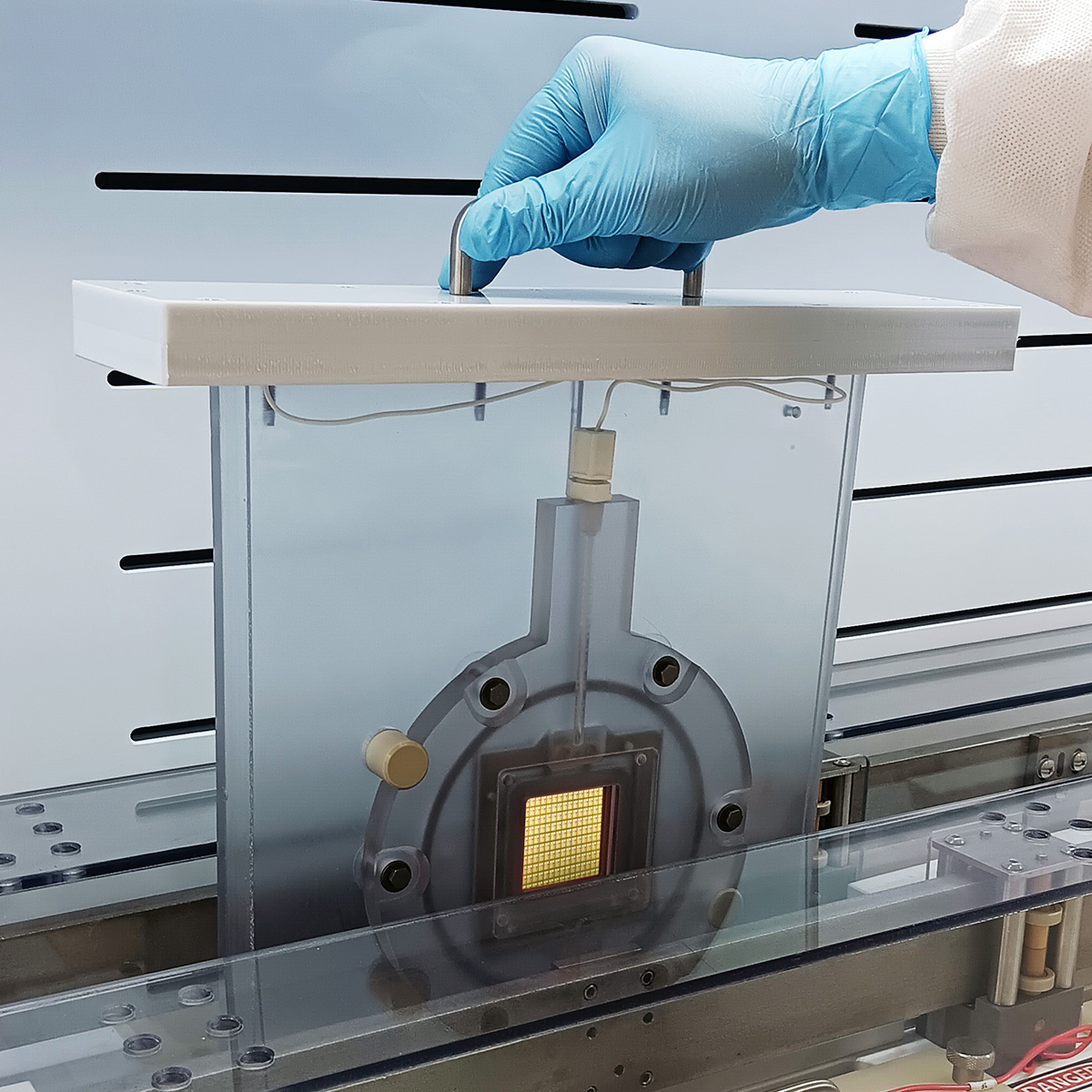

Semcon wafer racks are built from stable, chemically compatible materials, featuring gold-plated stainless steel contacts for low resistance and uniform current distribution. Custom-molded lip seals ensure effective leakage control with minimal pressure on the wafer. Designed for versatility and ease of use, the racks accommodate various wafer sizes, with replaceable seals, interchangeable cathode shields, and a removable cathode ring for easy loading and unloading.

Semcon Wafer Racks

Features

- Material Composition: Wafer racks are constructed from dimensionally stable, chemically compatible materials.

- Spring Contacts: Fabricated gold-plated stainless steel contacts provide low resistance and uniform current distribution.

- Molded Seals: Lip seal design provides superior leakage control while minimizing pressure applied to the wafer.

- Protected Contacts: Contacts are sealed, preventing exposure to plating solution, eliminating plate-up.

- Versatility: Available for round or rectangular wafer or panel size up to 200mm.

- Cathode Shielding: Interchangeable cathode shields are available for optimizing plating thickness uniformity.

- Ease of Use: Removable cathode ring simplifies loading/unloading.

Benefits

- Current Efficiency: Contacts do not rob current, ensuring superior plating uniformity.

- Backside Protection: Seals keep the backside of the wafer dry.

- Peripheral Contact: Seals allow peripheral contact within a 3mm exclusion area on the edge of the wafer.

- Low Maintenance: Protected contacts prevent plate-up and eliminate the need for stripping.

- Operational Efficiency: Ease of use through features like removable cathode rings and replaceable seals, reducing downtime.