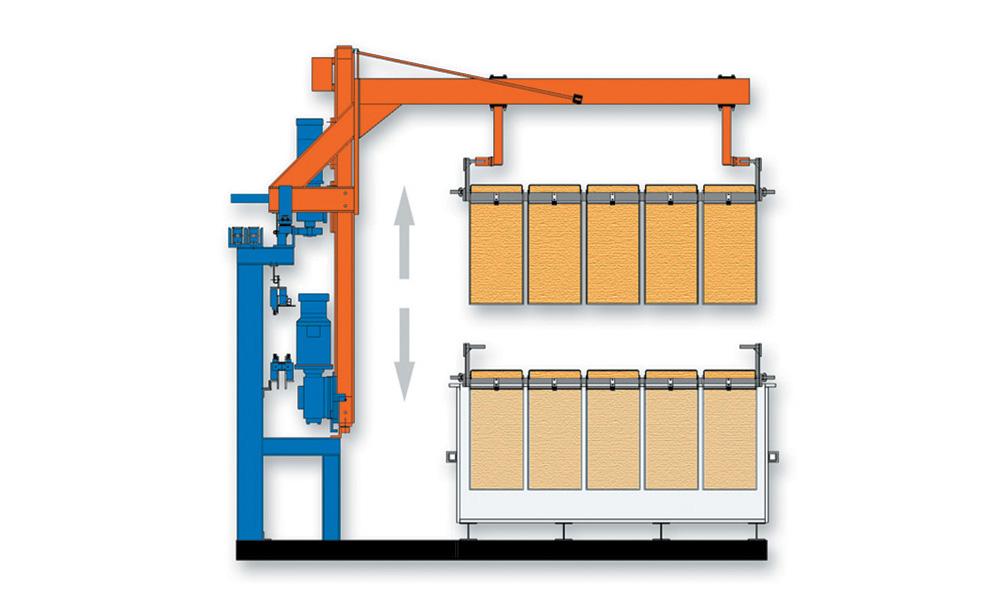

Sidearm Hoists are designed so that only the work boom travels over the tanks, thereby minimizing the potential for bath contamination during operation. Mounted to a single sided support structure, the rack/pinion drive motor and controls provide a smooth and stable movement over the processing area. The hoist’s vertical lift utilizes a roller chain and sprocket operation or optional belt lifting system for a steady and even vertical motion.

The affordability and compact design of this series makes it an ideal choice for retrofits and upgrades on existing lines.

MAC Series Sidearm Hoists

MAC 100: Lift Capacity 100 lbs.

MAC 250: Lift Capacity 250 lbs.

MAC 500: Lift Capacity 500 lbs.

MAC 750: Lift Capacity 750 lbs.

MAC 1000: Lift Capacity 1,000 lbs.

Sidearm Hoist Features & Specifications

Hoist Features & Specifications

- Drive System: Rack and Pinion

- Traverse Speed: 200+ fpm

- Lift Mechanism: Chain & Sprocket or Belt

- Station ID: Absolute Rotary Encoder or Laser

- Controls: Automatic, Semiautomatic and Manual

Line Construction Options & Features

Construction Options & Features

Technic offers a wide selection of custom built and turn-key hoist system designs*. All systems are pre-wired, pre-plumbed, and fully tested prior to shipment.

*Technic also supports the complete line of Baker Bros. "B" Series Sidearm Hoists.

- Tank Construction, Linings, Coating, Covers

- Loading/Unloading Stations

- Hoist Positioning Options

- Laser

- Encoder

- Manual

- Hoist Controls/Scheduling

- Random Loading

- Time-way Based

- Device Controls and Data Acquisition

- Rectifiers

- Heaters

- Pumps

- Filters

- Level

- Material Handling

- Rack

- Barrel

- Basket

- Plumbing

- Fill Lines

- Drains

- Spargers

- Inline or Offline Dryers

- Ventilation

- Spill Containment

- Enclosures (Hoist and System)

- Waste Treatment