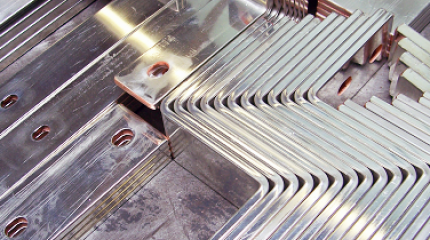

Technic's selection of world-renowned industrial plating chemistry also includes Pretreatment Chemistry, Electrolytic Plating Chemistry, Electroless Plating Chemistry, and Immersion Chemistry.

To further optimize the characteristics of your electroplated materials, Technic offers a range of post-treatment solutions for industrial finishing applications including anti-tarnish, passivation chemistry, coatings, and strippers.

Anti-tarnishes aim to prevent oxidation from developing on the metal surface. Technic’s extensive range of anti-tarnish products includes solutions for copper and copper alloys, steel, cast iron, silver, tin and tin alloys, etc.

Passivation processes are used to provide high corrosion resistance. Technic passivation chemistry, including solutions for alkaline, acid zinc and zinc alloys, is available in a variety of colors according to the level of corrosion resistance required. Coatings (top coats) may be used following passivation to further increase corrosion resistance for zinc and zinc alloys.

Technic’s advanced metal strippers are designed to ease the process of removing a certain metal from the plated surface. Technic has a range of strippers available compatible with a large variety of metals, such as copper, iron, steel, nickel and nickel alloys, brass, kovar and others.

Silver protection in high temperature and sulfur corrosive environments is an essential part of today's industrial technologies. Techniseal Ag is a powerful, electrolytic silver anti-tarnish process that deposits a nano-scale coating on the surface of the silver deposit.

Technic offers a range of anti tarnish chemistry for today's industrial manufacturers.

Technic offers a range of passivation chemistry for industrial manufacturers.

Technic's selection of world-renowned industrial plating chemistry also includes Pretreatment Chemistry, Electrolytic Plating Chemistry, Electroless Plating Chemistry, and Immersion Chemistry.